Client

Performance Food Group is a large food distribution and supply chain that is nationally recognized through 85,000 customer locations and 36 broadline locations. They engaged ASD® to replace their wireless infrastructure throughout their storage facility in Hickory, North Carolina.

Challenge

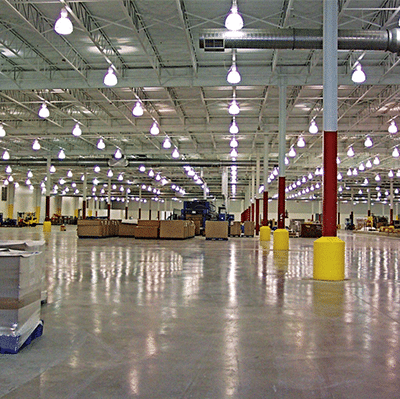

Performance Food Group’s facility has dry, refrigerator, and freezer storage, with each environment posing its own set of unique challenges. ASD® project managers had to find a way to update the wireless infrastructure without taking up too much space and compose a solution that could withstand the harsh temperature environments of the refrigerator and freezer spaces.

IMPORTANT CONSIDERATIONS

- How can we ensure flawless connectivity even in the freezer where temperatures are below 0?

- Will the freezing temperatures impact the installation process?

- With high ceilings and steel beams, what’s the best way to hang the wireless access points to ensure the signal is propagated correctly?

|

|

|

Solution

The cold storage areas, which totaled more than 280,000 sq. ft., were both kept at temperatures well below those recommended by manufacturers for the wireless access equipment. To combat this, special enclosures that were heated with POE were installed to house the equipment.

During these installations, the aerial platform lifts being used began to freeze up due to the cold temperatures. Technicians had to work in 30-minute intervals, taking the lifts in and out of cold storage, to keep the machine warm and operating.

The facility had high ceilings with steel beams, this posed a challenge because when the external antennas are too close to steel it can absorb and hinder the wireless signals. Our engineers decided to mount the antennas below the steel rafters and keep the access point above the rafters. This allowed the signal to propagate properly and minimized the amount of space they occupied.

|

Result

This wireless refresh project included the deployment of a new wireless barcode scanning software and a hardware system that previously had more limitations. The wireless barcode scanners were a production enhancement tool for the Performance Food Group staff allowing them to save time and operate more efficiently. The wireless access points in the freezer were deployed to extend the range of the scanners in an environment that was otherwise incapable of handling a wireless solution. The wireless equipment and infrastructure are now functioning properly, even with the steel beams and cold temperatures.