Client

Air Liquide is the world leader in gases, technologies, and services for industry and health. In the US they have over 1,300 locations and service over 2,000 miles of pipeline. Their industry and facilities are heavily regulated so picking a low voltage provider was no easy task, until they met ASD®.

Challenge

Air Liquide works with many flammable and dangerous substances, so they have very strict compliance and safety standards for their plants. They needed a vendor that would follow and enforce all of their policies in order to keep everyone safe. This meant there would be additional planning, screening, and preparation. ASD® project managers were up for the task.

IMPORTANT CONSIDERATIONS

- What steps can ASD® take to ensure all parties are safe and protected?

- What safety protocols must technicians follow to do work in the plants?

- How does the work need to be scheduled to minimize downtime and impact on the facilities?

|

|

|

Solution

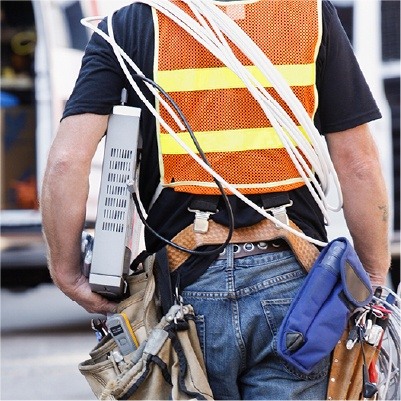

ASD® obtained the Avetta certification to prove that we were qualified for the job, passing all of the rigorous safety and financial requirements. From there, our senior project managers took over. They carefully scheduled work around the operating plants and ensured that technicians followed all of Air Liquide’s safety policies. Many technicians had to sit through several days of safety training before they were even allowed to enter a facility.

|

Result

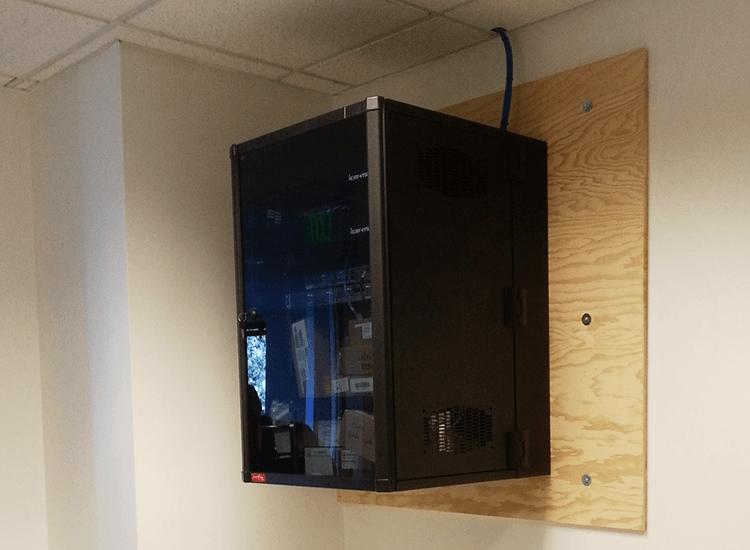

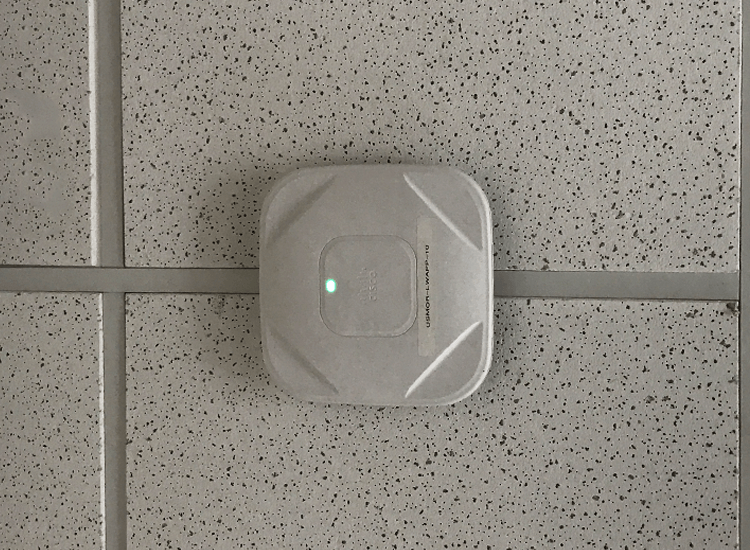

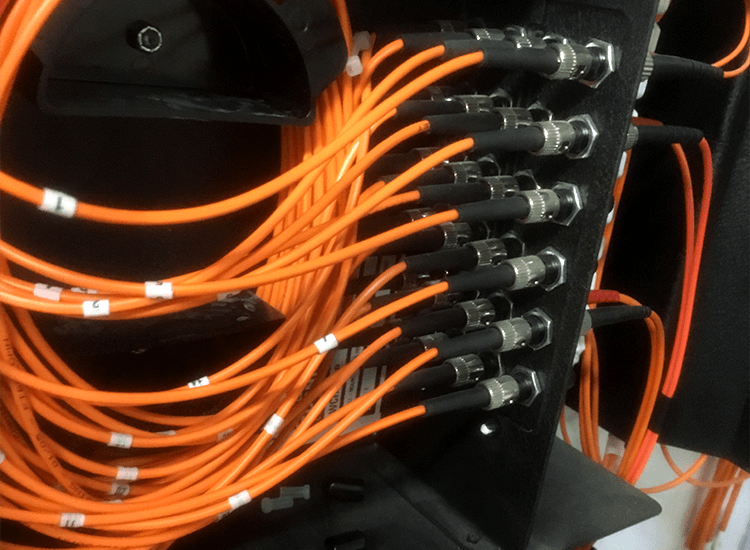

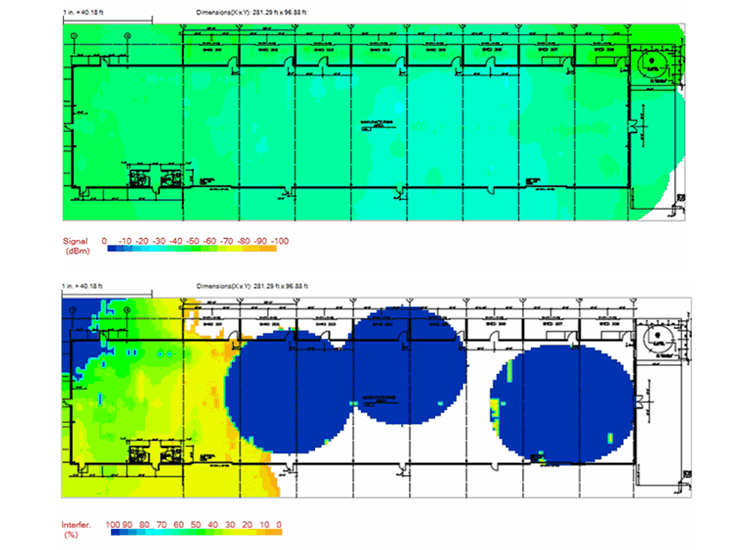

Ultimately, Air Liquide needed a partner, not just a vendor. With ASD® they found someone who cares about their products and safety just as much as they do. Project managers were able to update the structured cable, access control, and surveillance systems for several locations across the United States. Air Liquide employees can now work more efficiently and closely monitor all activity that occurs in the plants.